Kakaretso:ADX-600 ke resin ea ACR e hanyetsanang le khetla e entsoeng ka emulsion polymerization ke k'hamphani ea rona.Sehlahisoa se ka sebetsa e le phetoho ea tšusumetso bakeng sa PVC.ADX-600 impact ACR e ka nka sebaka sa CPE le MBS ho latela papiso ea mekhahlelo e fapaneng ea ts'ebetso lipakeng tsa tšusumetso ea ACR le li-modifiers tse fapaneng tsa PVC.Lihlahisoa tsa PVC tse hlahisoang li bonts'a thepa e ntle ea mochini, ts'ebetso ea ts'ebetso le ts'ebetso e phahameng e theko e phahameng.

Keyword:ACR, CPE, MBS, phetoho ea phello, thepa ea mochini

Selelekela

PVC e sebetsa e le polasetiki ea bokahohle e nang le kotulo e kholo ka ho fetisisa le sebaka se pharaletseng sa ts'ebeliso lefatšeng.E 'nile ea sebelisoa haholo likarolong tse kang thepa ea mohaho, lihlahisoa tsa indasteri, liphaephe tse sebelisoang letsatsi le leng le le leng, lisebelisoa tsa ho tiisa, likhoele, joalo-joalo.Leha ho le joalo, resin ea PVC ke ea lisebelisoa tse brittle.Karolo ea eona ea khalase e sa khaotseng e ke ke ea thibela ho atoloha ho matla ha mapetsong tlas'a khatello ea kelello 'me qetellong ho etsa likheo le ho phunyeha ho phatlohileng.Ka hona, mofuta o joalo oa thepa o bonts'a khanyetso e mpe ea tšusumetso.Leha ho le joalo, bofokoli bona bo ka hlōloa ka ho eketsoa ha phetoho ea phello ho thepa ea PVC nakong ea ho etsa le ho bopa.

Liphetoho tse ntle tsa phello li lokela ho hlahisoa ka likarolo tse latelang tse ntle:

(1) Mocheso o batlang o le tlase oa vitrification Tg;

(2) Ho tsamaellana ha mofetoleli oa tšusumetso ka boeona le resin ea PVC;

(3) Viscosity e tsamaellanang le liphetoho tse amanang le PVC;

(4) Ha ho na phello e mpe e totobetseng ho thepa e bonahalang le thepa ea 'mele le ea mechine ea PVC;

(5) Ho hanyetsa boemo ba leholimo bo botle le thepa ea ho ruruha.

Liphetoho tse tloaelehileng bakeng sa PVC e thata haholo li akaretsa chlorinated polyethylene (CPE), acrylate (ACR), ethylene-vinyl acetate copolymer (EVA), methyl methacrylate-butadiene-styrene ternary graft copolymer(MBS) le acrylonitrile-butadiene-styrene-ABScopolymer ).Har'a tsona, chlorinated polyethylene impact modifier e sebelisitsoe haholo Chaena mme acrylate le eona e ntse e amoheloa haholo ka lebaka la thepa ea eona e ntle haholo.E fetohile ho ameha ka kakaretso mokhoa oa ho ntlafatsa ho hanyetsa tšusumetso le ho nolofatsa extrusion ea polasetiki.

Sehlahisoa sa rona sa ACR ADX-600 se ka nka sebaka sa CPE le MBS.E ka ntlafatsa haholo ho feto-fetoha ha metsi le mocheso oa PVC ho qhibiliha 'me kahoo e nolofatse polasetiki ea PVC.Lihlahisoa tse hlahisoang li bonts'a matla a ts'ebetso e phahameng le ho hanyetsa boemo ba leholimo bo botle, botsitso le thepa ea ho sebetsa e nang le sebaka se boreleli, se setle le se benyang haholo.Ka mor'a moo, re hlahlobile ACR, CPE le MBS likarolong tse latelang.

I. Mechanism of Toughening by PVC Impact Modifiers

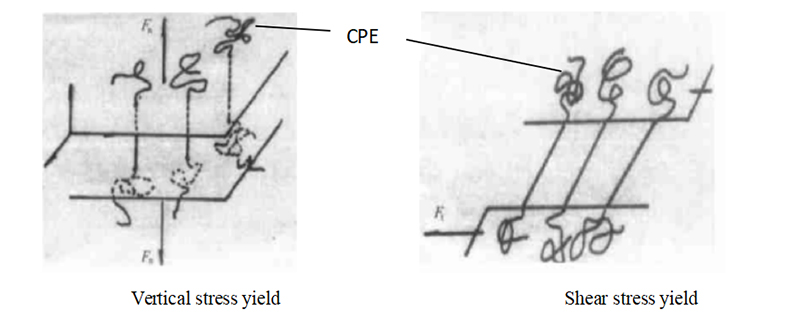

Chlorinated polyethylene (CPE) e sebetsa e le limolek'hule tsa mela tse qhalakantsoeng ka har'a matrix a PVC ka mokhoa oa marang-rang.Molao-motheo oa ho hanyetsa tšusumetso ke ho theha marang-rang a elastic ka thepa ea matrix ea PVC e le ho hanela tšusumetso ea kantle.Marang-rang a joalo a na le tšekamelo ea ho holofala tlas'a matla a thata.Sena se tla etsa hore ho thellehe ha motsoako ka lehlakoreng la 30 ° ho isa ho 45 ° ho tloha ka lehlakoreng le thata, ka hona ho theha sehlopha sa ho kuta, ho monya matla a mangata a deformation, le ho matlafatsa botsitso ba sistimi ea motsoako.Liphetoho tsa tlhahiso ea khatello ea maikutlo ea thepa tlas'a matla a ka ntle li bontšoa ka lipalo tse latelang.

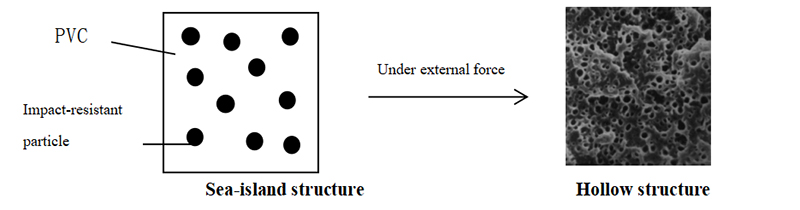

ACR le MBS ke tsa mofuta oa "core-shell" copolymer impact modifier.Mokotla oa eona o sebetsa e le elastomer e hokahaneng e tlase, e bapalang karolo ea mantlha ntlafatsong ea botsitso le ho hanyetsa tšusumetso.Khetla ea eona e sebetsa e le polymer e phahameng ea molek'hule e nang le mocheso o phahameng oa vitrification, e bapalang karolo ea mantlha ho sireletseng mokokotlo oa rabara le ho ntlafatsa ho lumellana le PVC.Mofuta ona oa likaroloana tsa mofetoleli o bonolo ho aroloa 'me o ka qhalakanngoa ka ho lekana ka har'a matrix a PVC e le ho etsa sebopeho sa "sehlekehleke sa leoatle".Ha thepa e le tlas'a tšusumetso ea ka ntle, likaroloana tsa rabara tse nang le modulus e tlaase li atisa ho fetoha.Ka nako e ts'oanang, de-bonding le cavity li thehoa ha thepa e tsamaisoa ke deformation ea PVC e nang le modulus e phahameng.Haeba masoba ao a le haufi ka ho lekaneng, lera la matrix pakeng tsa likaroloana tsa rabara le ka hlahisa le ho ntlafatsa ho tiea ha thepa.Molao-motheo o hanyetsanang le tšusumetso o bontšoa setšoantšong se ka tlase.

CPE, ACR le MBS li bonts'a kutloelo-bohloko e fapaneng ho matla a machining ka lebaka la mekhoa ea tsona e fapaneng e thata.Nakong ea ts'ebetso, likaroloana tsa ACR le MBS li ajoa ka har'a matrix ea PVC ka ketso ea ho kuta, ho etsa sebopeho sa "sehlekehleke sa leoatle" mme ka hona ho matlafatsa botsitso ba thepa.Leha matla a ts'ebetso a ntse a eketseha, sebopeho sena se ke ke sa senyeha habonolo.Phello e matla ka ho fetisisa e ka phethahala feela ha mofetoleli oa CPE le PVC li kopantsoe mohahong oa marang-rang o kenyang likaroloana tsa PVC tsa mantlha.Leha ho le joalo, sebopeho sena sa marang-rang se ka senyeha habonolo ka lebaka la liphetoho tsa matla a ho sebetsa.Ka hona, e na le maikutlo a matla a ts'ebetso 'me e sebetsa ho mefuta e fokolang ea ts'ebetso.

II.Papiso ea Thepa e fapaneng lipakeng tsa ADX-600 Impact ACR le Liphetoho tse fapaneng tsa PVC Impact

1. Foromo ea Teko ea Base

| Lebitso | Setsi sa mocheso oa Organo-tin (HTM2010) | Calcium stearate | Titanium dioxide | PE-6A | 312 | Calcium carbonate | PVC-1000 |

| Tekanyo/g | 2.0 | 0.7 | 4.0 | 0.6 | 0.2 | 5.0 | 100.0 |

2. Thepa ea tšusumetso

| Lintho | Mabitso a mehlala | Litekanyetso tsa liteko | Diyuniti | Chelete e ekelitsoeng(phr) | |||||

| 3 | 4 | 5 | 6 | 7 | 8 | ||||

| Tšusumetso e tsoang ho notched cantilever beam | ADX-600 | ASTMD256 | KJ/m2 | 5.44 | 6.30 | 7.78 | 8.72 | 9.92 | 12.02 |

| ACR e tsoang linaheng tse ling | KJ/m2 | 4.62 | 5.01 | 7.68 | 8.51 | 9.63 | 11.85 | ||

| MBS | KJ/m2 | 5.32 | 5.39 | 7.52 | 8.68 | 9.78 | 11.99 | ||

| CPE | KJ/m2 | 3.54 | 4.25 | 5.39 | 6.32 | 7.01 | 8.52 | ||

| Tšusumetso e tsoang ho beam ea cantilever e se nang notch | ADX-600 | J/m | 57.03 | 63.87 | 72.79 | 88.23 | 100.09 | 121.32 | |

| ACR e tsoang linaheng tse ling | J/m | 46.31 | 50.65 | 72.55 | 85.87 | 97.92 | 119.25 | ||

| MBS | J/m | 53.01 | 62.07 | 71.09 | 87.84 | 99.86 | 120.89 | ||

| CPE | J/m | 21.08 | 37.21 | 47.59 | 59.24 | 70.32 | 82.21 | ||

3. Thepa ea ho otlolla / e kobehang (Lipalo tsohle tsa tlatsetso ke 6phr)

| Lintho | Litekanyetso tsa teko | Diyuniti | Matšoao a tekheniki(ADX-600) | Matšoao a tekheniki(ACR e tsoang linaheng tse ling) | Matšoao a tekheniki(MBS) | Matšoao a tekheniki(CPE) |

| Tensile elasticity modulus | ASTM D638 | MPa | 2546.38 | 2565.35 | 2500.31 | 2687.21 |

| Sehlahisoa sa Tensile Elongation | ASTM D638 | % | 28.38 | 27.98 | 26.84 | 17.69 |

| Matla a tšepe | ASTM D638 | MPa | 43.83 | 43.62 | 40.89 | 49.89 |

| Modulus e kobehang | ASTM D790 | MPa | 2561.11 | 2509.30 | 2528.69 | 2678.29 |

| Matla a kobehang | ASTM D790 | MPa | 67.39 | 65.03 | 66.20 | 69.27 |

Tlhahlobo: Ho latela lintlha tse kaholimo mabapi le thepa ea mochini:

① Tlas'a litekanyetso tse tšoanang, ts'ebetso ea sehlahisoa sa rona sa ADX-600 e betere ho feta ea lihlahisoa tsa MBS le ACR tse tsoang linaheng tse ling.Sehlahisoa sa rona se ka li nkela sebaka ka chelete e lekanang.

② Tlas'a litekanyetso tse tšoanang, ts'ebetso ea sehlahisoa sa rona sa ADX-600 e phahame haholo ho feta ea CPE.Ho ipapisitsoe le liteko tse ngata, ho netefalitsoe hore litekanyetso tse 3 tsa ADX-600 le 3 tsa CPE li ka nka sebaka sa tšebeliso ea litekanyetso tse 9 tsa CPE.Thepa e khethehileng ea mechine e bontšoa ka tsela e latelang.

| Lintho | Litekanyetso tsa teko | Diyuniti | Matšoao a tekheniki(ADX-600/3phr+CPE/3phr) | Matšoao a tekheniki(CPE/9phr) |

| Tšusumetso e tsoang ho notched cantilever beam | ASTM D256 | KJ/m2 | 9.92 | 9.86 |

| Tšusumetso e tsoang ho beam ea cantilever e se nang notch | ASTM D256 | J/m | 97.32 | 96.98 |

| Tensile elasticity modulus | ASTM D638 | MPa | 2250.96 | 2230.14 |

| Sehlahisoa sa Tensile Elongation | ASTM D638 | % | 101.25 | 100.24 |

| Matla a tšepe | ASTM D638 | MPa | 34.87 | 34.25 |

| Modulus e kobehang | ASTM D790 | MPa | 2203.54 | 2200.01 |

| Matla a kobehang | ASTM D790 | MPa | 60.96 | 60.05 |

4.Ho sebetsa Liketso

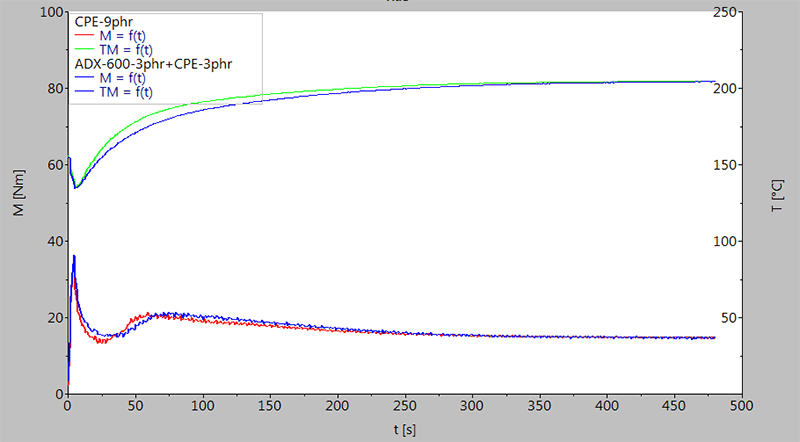

Setšoantšo se ka tlase se bontša lekhalo la rheological.Mohala o mofubelu: ADX-600 / 3phr + CPE / 3phr;mola o moputsoa: CPE/9phr

Li-torque tse peli tse leka-lekaneng ha e le hantle li tšoana, 'me plastification ea thepa e fetotsoeng ke ADX-600 / 3PHr + CPE / 3PHR e lieha hanyenyane empa e ka laoloa ho ea ka palo.Ka hona, mabapi le ts'ebetso, litekanyetso tse 3 tsa ADX-600 hammoho le litekanyetso tse 3 tsa CPE li ka nka sebaka sa tšebeliso ea litekanyetso tse 9 tsa CPE.

III.Liqeto

Ka papiso lipakeng tsa ADX-600 impact ACR le CPE le MBS ka thepa ea mochini le boits'oaro ba ts'ebetso, sephetho se latelang se fihletsoe tlhahlobong ea sepheo sa hore litekanyetso tse 3 tsa ADX-600 le litekanyetso tse 3 tsa CPE li ka nka sebaka sa ts'ebeliso ea litekanyetso tse 9 tsa. CPE.Tšusumetso ea ADX-600 ACR e bonts'a ts'ebetso e phethahetseng e felletseng, eo lihlahisoa tsa eona li bonts'ang ts'ebetso e betere le ts'ebetso e theko e phahameng haholo.

ADC-600 impact ACR ke ea acrylate copolymer e nang le sebopeho sa khetla ea mantlha.ACR e bonts'a boemo ba leholimo bo betere, botsitso ba mocheso le sekhahla sa litheko ho feta MBS hobane ea pele ha e na bond e habeli.Ntle le moo, ACR e boetse e bonts'a melemo ea mefuta e mengata ea ts'ebetso, lebelo la extrusion ka potlako, taolo e bonolo, joalo-joalo E sebelisoa haholo ho lihlahisoa tsa PVC tse thata le tse thata, haholo-holo bakeng sa lisebelisoa tsa kaho tsa lik'hemik'hale le lihlahisoa tsa kantle, joalo ka profil, liphaephe, Lisebelisoa tsa liphaephe, liboto, thepa e phophomang, joalo-joalo. E sebetsa e le mofuta oa phetoho e nang le litekanyetso tse kholo hona joale le bokhoni bo boholo bo ntseng bo eketseha nakong e tlang.

Nako ea poso: Jun-20-2022